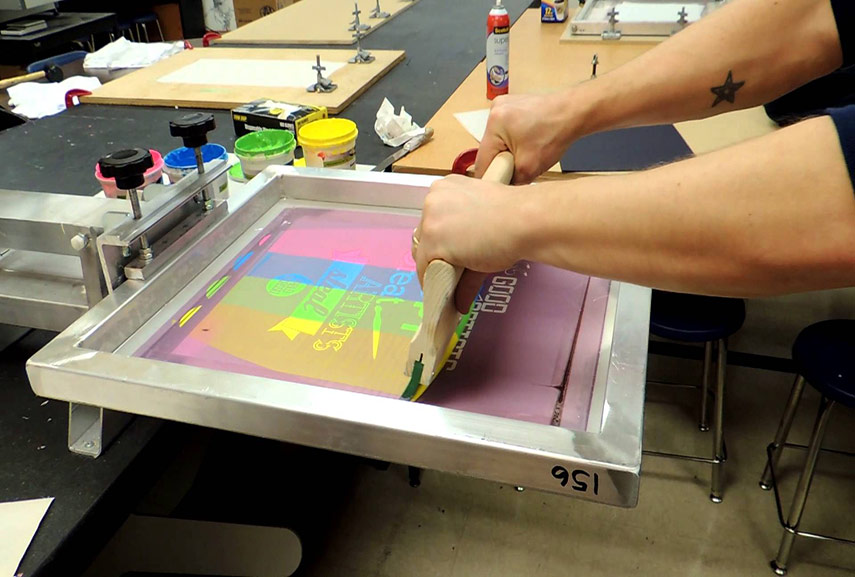

Screens and setup make display screen printing too costly for low-quantity customized orders. Many envision a future the place customers order online and a DTG printer routinely prints the shirt. While many businesses have tried this, the technical and labor challenges have confirmed tremendous . DTG printing is not as simple as pushing a button – there are many variables and components to consider. Most DTG printing retailers use a curing dryer or warmth press to treatment their products. The screen is placed on a display screen printing press and registered so it's going to properly align on the printing surface (typically, a t-shirt). Ink is pressed via the openings within the stencil with a squeegee, immediately making use of ink onto the printing floor.

People now choose to mix pictures with inventive additions for colorful graphics which would possibly be artistic endeavors quite than easy shirt prints. And DTG printers can produce wonderful outcomes on both mild and dark-colored fabrics. Later on, in the 17th century, silk screens have been used as a extra environment friendly and elegant means of printing. Stiff brushes have been used to drag the ink by way of, but color options have been still limited throughout this era. The two hottest apparel printing methods are Screen and DTG (direct-to-garment) printing. Screen printing will produce a vibrant, durable design with more saturated colours than the DTG process.

With decades of experience in embroidery technology, Ricoh has begun its acquisition and expansion phase. AnaJet invested heavily in shopper education and ongoing help for their DTG users, making it a good match for Ricoh's solutions-oriented business mannequin. Ricoh is multinational corporation focused on offering digital options to businesses. They make an intensive line of DTG printers for quite so much of industrial applications.

The vinyl heat-transfer process makes use of a machine to chop out particular person letters and designs from items of coloured vinyl. The full picture is then pieced collectively on the promo item and pressed with warmth to switch the image to the merchandise. This technique is greatest suited to printing sportswear jerseys, slogans, or small, multi-colored graphics. Screen printing is extensively considered the most popular method of printing. Because it’s very price effective for printing large batches of attire, especially if printing all the identical shade.

Some DTG printers may cost extra for detailed designs as they know that this isn't one thing that works well when screen-printing, which supplies the brand new methodology a determined edge. The results you get from DTG garments are long-lasting and can easily go through lots of of washes. The printed clothes might vary from type and ink absorbency, however the print result is simple. Teams and organizations have to mass-produce their shirts and apparel to help represent them when they’re collaborating in or internet hosting their occasions. The wants of an event should be fast, and DTG printing presents simply that. The added capacity to allow clients to customise their printed tasks can further enhance the profit margins. Selling on-line with a easy kind for personalization ensures what the shopper fills out is what they get.

Since you do not have to separate or burn screens, screen printers are ready to use DTG printing on artwork that simply would not translate nicely to the display screen printing press. Then, the print is often cured in a heated dryer – for plastisol, the commonest display printing ink, it is heated to 320 levels F . A unfavorable image is printed , then "burned" into the emulsion with a strong light. The emulsion cures , however the negative picture stays as a water-soluble paste.

Imri Merritt works in artwork, design and advertising for Rush Order Tees, a division of Printfly Corp. See the unique version of this story on the Rush Order Tees blog. A quality DTG print can potentially get dozens of washes before it begins fading. With DTG, the inks are water-based and more clear than plastisol. This allows the ink to overlap and mix, making stunning, clean gradients, and giving DTG the successful edge in this round. As a outcome, operators share the love and cross on their financial savings. Pricing is essential, however the worth that DTG brings can be in velocity, effectivity, and turnaround time.

Special results printing is all about adding further dimensions to a print. From raised print to textures to shines and sparkles and glows, there’s a specialty ink or additive that may do it. The better part is you'll have the ability to combine many of these for creations which are restricted only by your imagination . Versatility on this context is the flexibility to print on quite lots of textiles, as properly as a variety of garment styles, print places and placements.

Because it's digitally printed by a machine, there’s no restrict to the kinds of designs and the number of colors you ought to use. Although it's a nice option for elaborate designs on t-shirts, it does make it costly compared to display printing. As with all things, there are all the time exceptions to the rules. If your goal is custom shirt cheap, check out bulk pricing information.

The equipment used in display screen printing are quite cumbersome and wish plenty of area – https://www.achievementlearn.com/ most positively not a back-office affair. Cut the vinyl – the cutter has blades that minimize the shape you design out of the vinyl. DTG printing presents many advantages over traditional silk-screening. There are certain conditions where you would definitely need to opt for DTG over silk screening, and vice versa.

As you can see, each DTG and Dye Sublimation printing is ideal for the small and medium-sized t-shirt printing enterprise. The know-how to get into each forms of printing is affordable, and you can begin making good money by providing the next quality product than what many display screen printers can put out. Sublimation printing offers you full management of where you need to place your design on the garment. This methodology also works nice for placing multiple designs on the same t-shirt. You can combine sublimation printing with cut and sew to create actually distinctive designs.

Don’t underestimate the importance of your pre-treatment machine! Lawson, Equipment Zone and M&R all make pre-treatment machines for DTG printing . Pre-treatment provides appreciable time and price to DTG printing. This is usually a "blind spot" that display printers encounter once they make the leap to DTG printing. If you see that artwork can simply be separated, lean towards display printing. Since display printing sometimes isn't profitable at small volumes, DTG printing presents an affordable alternative for customers that want fewer than 12 pieces.

Israel-based Kornit competes on this house, backed by a large investment from Amazon's print-on-demand division. Despite pouring tons of of tens of millions into the print-on-demand area, Amazon continues to be not the dominant player in the market. Regardless, Kornit has significantly superior the whole DTG printing industry from a technological standpoint. STAHL's offer a DTG return-on-investment calculator that allows you to determine the time to profitability. Pre-treat can be costly (Ryonet sells a 20 liter provide of Epson's pre-treat for just below $700) – nevertheless it's needed for professional-quality prints. Remember, the objective is toadd valueby meeting your buyer's needs! Unless you specialize in printing complicated art, lean towards DTG for things like pictures .

This technique is a method where a special printer and warmth press is used to dye ink utilized on a shirt. In 1960 a man by the name of Michael Vasilantone developed a rotary multicolor garment display screen printing machine. Not only did it gain reputation at that time, however the machine’s origin and elegance are still used right now. And this invention began the t-shirt revolution of customized shirt prints. The scope of your customized t-shirt printing project ought to be a consideration as you select a printing service to handle it. Some custom attire companies supply just one or the opposite, while some offer each DTG and screen printing choices depending on the size of your project. There isalways a print shop that has more expertise than you do.

Want to know extra in regards to the completely different strategies of printing and their very own distinctive advantages? While each methods provide options to getting a design onto a t-shirt or different product, display printing and warmth transfers are every great for various causes. When you first start printing your t-shirts, the primary decision to make is the printing technique. There are all kinds of different ways to plaster your design onto material. Methods include heat-transfer, sublimation, display screen printing, direct-to-garment, and lots of others.

Although the method uses a system of spot coloring, halftones and blends, it might be used to create a picture that appears to have a numerous variety of colors. Screen printing as a production technique shortly overtakes Digital Printing in price per print.